|

|

|

|

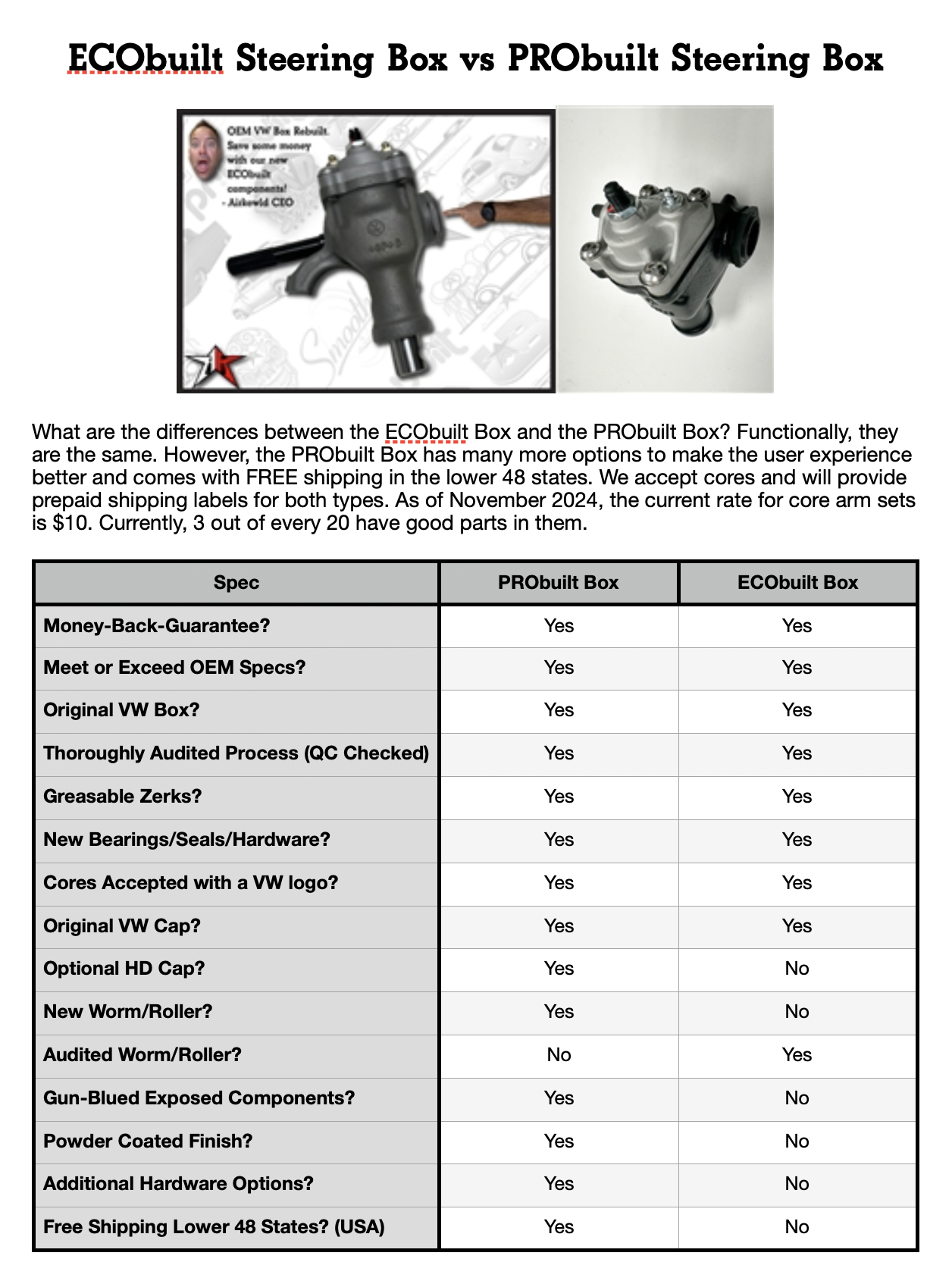

The most often neglected part of the Classic Volkswagen Drive-Train is the Steering Box. The 113415061C, which is the factory OEM part number, is the most common steering box used. It will work with *All Type 1's, Type 3's, Type 181's and anything that came with a Ball Joint front suspension. ECObuilt Components are no longer shipped for free.

Adjusting the steering box with the adjustment on the top of the box is often over used. As a whole, the steering box is responsible to 40% of the steering wheel play/creep in the steering system. Crazy, right? There is SO MUCH MORE that is responsible for play/creep but we as consumers assume, the steering box is the reason.

What plays a role in play in the Steering System?

Steering Wheel connection to the steering shaft (proper torque)

Steering Shaft connection to the male steering tee (proper torque)

Male steering tee to the rag joint (rubber doughnut) (proper torque)

Rag joint to the female steering box tee (proper torque)

Female steering box tee to steering box (proper torque)

Steering Box (proper adjustment - set to spec by the PRO's)

Steering Box to beam connection (proper torque)

Steering Box to pitman (drop arm) connection (proper torque)

Pitman arm connection to the inner right tie rod end (proper torque+creep/deflection in the joint)

Pitman arm connection to the inner left tie rod end (which needs to be bent) (proper torque+creep/deflection in the joint)

Steering Dampener (with or without)

Tie rod Ends (4x)

(Just because it is new does not mean the quality control (QC) of each

manufacture is equal to one another, they are all different)

(proper torque+creep/deflection in the joint)

Left inner tie rod end to tie rod (proper torque)

Right inner tie rod end to tie rod (proper torque)

Left outer tie rod end to tie rod (proper torque)

Right outer tie rod end to tie rod (proper torque)

Left outer tie rod end to spindle

(proper torque+creep/deflection in the joint)

Right outer tie rod end to spindle

(proper torque+creep/deflection in the joint)

Upper Left Control Arm to Beam engagement (play/creep in the rotating system - arm to bearing/bushing)

Lower Left Control Arm to Beam engagement (play/creep in the rotating system - arm to bearing/bushing)

Upper Right Control Arm to Beam engagement (play/creep in the rotating system - arm to bearing/bushing)

Lower Right Control Arm to Beam engagement (play/creep in the rotating system - arm to bearing/bushing)

(Link Pin Equipped VW's)

Link pins to arms (proper torque)

King pins (proper reamed fit to bushings along with proper thrust to the carrier)

Drum or Disc Bearing connection (correct thrust on the bearings)

Lug Nuts (correct lug nut to wheel along with proper torque)

Tire load rating or tire pressure (less pressure, more sway, more pressure, less sway)

(Ball Joint Equipped VW's)

Ball Joints (4x)(Just because it is new does not mean the quality control (QC) of each

manufacture is equal to one another, they are all different -

Once the joint is pressed in, it need to be broken in to have the proper thrust in the joint)

Ball Joint connections to the spindle (proper torque)

Drum or Disc Bearing connection (correct thrust on the bearings)

Lug Nuts (correct lug nut to wheel along with proper torque)

Tire load rating or tire pressure (less pressure, more sway, more pressure, less sway)

Crazy to think how much contributes to the overall steering experience.

Made in the USA | Product updated 10/25/24 by Pete

Related: Premium Tie Rod Ends | Steering Dampener

Typical time to install - 4 Hours | Install PDF Link | Install Video | What's the difference between the ECObuilt & the PRObuilt Boxes?

What's included?

This OEM ECObuilt Steering Box comes with the following;

- OEM VW Steering Box Case

- OEM VW Steering Box Top

- OEM VW Audited Worm Gear

- OEM VW Audited Roller Shaft

- OEM VW Worm Adjuster

- OEM VW Worm Adjuster Nut

- New Seals

- New Stainless Hardware

- Grease-able Zerks Installed

- NOS Roller Bearings

- New Jam Nut

How it's Made

Disassembly

- Remove jam nut and cap bolts, remove cap.

- Center roller on

worm and remove roller via hydraulic press.

- Remove circlip, spacer and

adjuster from roller.

- Remove worm adjuster and jam nut from steering box

case.

- Separate adjuster and jam nut via bench vice.

- Remove worm, end

bearing and alignment ring from case.

- Remove worm seal, case washer and

shaft bearing from steering box case via press.

- Clean, degrease, inspect

and flatten case washer as needed.

- Remove roller shaft seal from case

via vice.

- Steering box case prep-Bench grind, belt sand and die

grind casting marks, dents and imperfections.

- Barrel sand worm shaft

seal opening.

- OEM Roller prep

- Clean/Degrease, inspect as needed.

- Wire wheel,

belt sand (chamfer) and lathe sand shaft assy.

- Test fit in steering box

case.

- Install adjuster, spacer and spacer, check for proper

seating of cir-clip

OEM Cap prep

- Audit cap, tap

and clean grease fitting holes, die grind dents and imperfections,

sandblast, hone roller shaft seat.

- Oil soak.

Steering box parts

prep

- Inspect parts & clean

worm.

- Oil soak.

- Audit, belt sand, sandblast worm adjuster and jam nut,

belt sand and sandblast roller adjuster.

Reassemble

- Acetone

clean bearings, grease pack, grease pack seals.

- Install seals, install

case washer, install worm and new bearings.

- Seat new bearings, adjust

worm, install Teflon tape to worm adjuster and install jam nut.

- Fill

steering box case with appropriate amount of corn-head grease.

- Grease

and install roller assy making sure for proper alignment.

- Install cap

and gasket. Torque to spec.

- Adjust steering box assembly on bench jig to

Airkewld specs, clean and audit as needed.

What's recommended?

- If you have a pre-1961 Type 1 VW, and you still have the original steering box, your will need a 1962 through 1968 steering box pitman/drop arm. It will have the appropriate gear and tie rod end holes.

- If your rag joint is looking....ragged, it is time to update to the OEM PRObuilt version found here.

- With the help of a buddy, audit the entire steering system on the Classic Volkswagen by one person rocking the steering wheel and the other checking the connections while the vehicle is on the ground.

Kewl Features

- Greaseable zerks

- The serrations on the worm gear are sharp and will allow for proper

adhesion when the clamp is tightened, something the aftermarket boxes

lacked.

- Upon

receiving your OEM ECObuilt Steering Box, it will be filled with Corn

Head Grease and it will not need to be serviced in your lifetime. It

will not need to be adjusted out of the box. If you have more or less

place after installation, you need to check out all the other

connections that play a roll in the steering system.

FAQ

- Do I need to fill this steering box with grease? No. It comes filled with the correct amount of Corn Head grease.

- My steering box has play in it, should I adjust it? No. Check all the other steering system connections first, this is often over-looked, even the proper torque on the connections has been a leading cause of "play" in the system.

- If everything else in my steering system has been audited and checked, and still has play, can I adjust it? Call us first, 1-623-518-3537.

- What can I do with my core steering box? If it has a VW logo on it AND looks similar to the one that is replacing it, the PRO's do have a Core Parts Program here to get the core coming to us. The PRO's DO NOT want any TRW, Ampri or other brands in any fashion.

|

|

|

|

|

|

|

|

|

|

|

|

|

What does this fit?

1962 through 1977 Type 1 Beetle-Bug-Fusca

1962 through 1975 Karmann Ghia

All Type 3's

1973 and 1974 Type 181 Thing

Mexican Beetle

Fridolin

Kit cars with ball joint suspensions

Fits the following if you replace the early pitman/drop arm and install a 1962-68 pitman/drop arm, (which is now an option):

1949 through 1961 Type 1 Beetle-Bug-Fusca

1957 through 1961 Karmann Ghia

Kit cars with link pin suspensions

|

|

|

|

|

|

| Accessories, check the box to include with your order. |

|

|

|

|